Strictly speaking (according to the ASQ the American Society for Quality), a quality management system is:

A formalized system that documents the structure, responsibilities and procedures required to achieve effective quality management.In other words, it is a blueprint for how quality will be achieved and maintained within an organization.

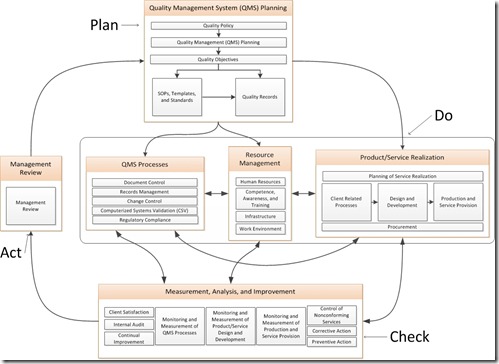

Recently I had the opportunity to develop the Quality Manual for a project I was working on. I used ISO 9000 as a reference standard / checklist to ensure I included all the appropriate elements. (You can find a link to ISO in the sidebar.) As I was mapping the interrelated processes described in the QMS (and shown in the figure below) it occurred to me that I was creating a supersized PDCA cycle. The PDCA cycle (which stands for Plan-Do-Check-Act, also known as the Shewart cycle or Deming cycle) is a four-step process for quality improvement.

Figure 1. Quality Management System in a regulated environment

Step 1: Plan

In this step, you develop a way to build quality into the product or service you intend to produce and also a way to improve that product or service. In a QMS, these are the Quality Management System Planning processes. These plans include not only planning the realization of the product/service, but also the management of the resources to product the product/service, and also the QMS processes to ensure and improve the quality of the product/service.

Step 2: Do

In this step, you carry out your plans from Step 1: product/service realization, resource management, and the processes of the QMS.

Step 3: Check

The third step is to compare what you produced with what you planned. These are the Measurement, Analysis, and Improvement processes of the QMS. These activities breakdown into two areas: quality assurance and quality control. While both are often used interchangeable because they both concern ensuring the quality of the product/service, quality assurance is about the processes you use to ensure quality and quality control is about the product itself.

Step 4:Act

The last step is to review results of the operations of the QMS and decide whether your objectives have been met and whether or not changes should be made to meet your objectives. Based on the results of this Management Review processes within the QMS, if changes are required your next move is back to Step 1: Plan and the continuous improvement cycle begins again.

No comments:

Post a Comment